DESCRIPTIONMaintenance-free + Easy maintenance

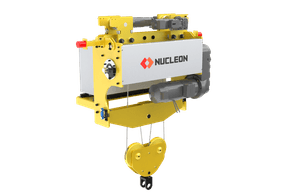

Double girder gantry crane is a large-scale loading machine widely used in open-air material handling. It has the advantages of large lifting capacity, large working space, high utilization rate of freight yard area, low infrastructure investment, and low operating cost. Therefore, it is widely used in industrial and mining, transportation, transportation, engineering construction and other departments.

The whole crane consists of four parts, box type girder, crane traveling mechanism, crab traveling mechanism, and electrical equipment.

Double girder gantry crane frequency conversion speed control system can provide smooth acceleration characteristics and a variety of operating speeds, smooth starting and braking, simple operation and accurate positioning. Adopting high-quality, high-quality parts, the product is durable, safe and reliable, which greatly reduces the maintenance cost of the crane. At the same time, the total installed power (energy consumption) is also reduced, saving the cost of use. The crane is mature, reliable, easy to operate, smooth running and technologically advanced.

Double girder gantry cranes are available for general service, such as loading, unloading, lifting and transferring work in ports, mines, warehouse, docks and outdoor yards of the factory or on railways.

PRODUCT FEATURESReliable performance & improve production efficiency

- Light weight, small wheel pressure, reliable performance.

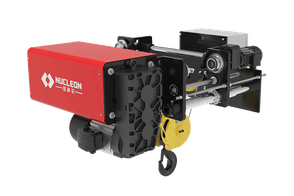

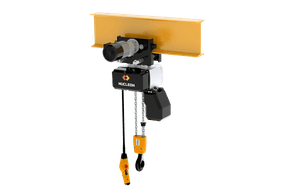

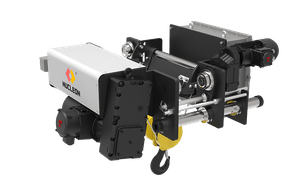

- The trolley adopts compact structure, hard tooth surface reducer, rolling pulley, welded drum, small size and light weight.

- Increase the scope of hook operation, improve production efficiency.

- The mechanism adopts direct connection type, reduces transmission links, reduces the number of fault points, improves transmission efficiency, and reduces the energy consumption of the crane.

- The operating mechanism adopts three-in-one decelerating motor, variable frequency speed regulation, smooth starting and braking without impact.

- 65Mn forged wheel, wear-resistant, long service life.

- Options: anti-swing function, vertical lifting function, remote control function, automatic and semi-automatic control function.

Product AdvantagesThe crane is safety supervises system and technologically advanced

- The crane and trolley frame adopts floor type boring machine to ensure the flatness of the machine side.

- The safety supervises system is equipped with overload limiter, and on the monitor it can display the loads value and remind the operator to prevent the overload happening.

- Before the start, the entire controller will start self-checking including: power voltage, default phase, the effective of each safety protective device and zero position of the button.

- Adopts imported with original packaging from Germany, The brake force shall no less than 2160N/mm2, and its safety factor shall no less than 5.

- Imported motor with insulation grade is F, and protective grade is IP54, it also have over heated and alarming function, the motor cover adopts aluminum alloy to drawing the molding, with better heat dissipation.

- Germany imported reducer, harden face gear, improve the bearing ability, better sealing of the shell, ensure there no grease penetration.

- The main electric elements adopts the international brands include Schneider, Siemens, ABB. The protective grade of the electric control box is no less than IP 54.

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.