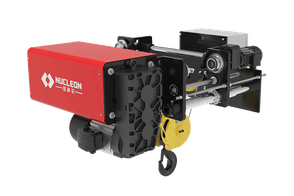

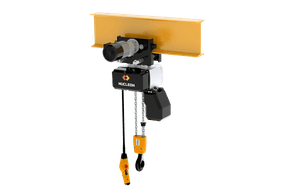

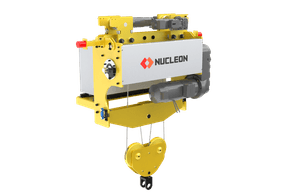

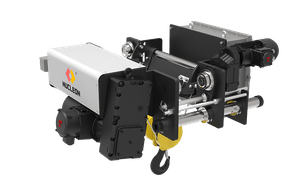

DESCRIPTIONLightweight, modular and parametric design

Double girder overhead cranes adopts lightweight, modular and parametric design. Hoisting mechanism uses NRT crab mode electric hoist with superior performance and advanced technology. Traveling mechanism of trolley is drove by three-in-one drive device and the control mechanism adopts the advanced variable frequency and speed regulation control system.

The crab frame of the crane adopts an "H" shape structure composed of one or two crossbeams and two longitudinal beams. The crossbeam of small tonnage crane beam is placed in the middle of the beam span at both ends, one side is rigidly connected with the end beam, and the other side is hinged with the end beam. This structure not only ensures that the crab wheel can contact with the track under any working condition, but also reduces the manufacturing accuracy requirements of the crab frame.

The working ambient temperature is generally -25 degrees ~ 40 degrees. Yet it is forbidendded to work in environment that is combustible, explosive or corrosive.

PRODUCT FEATURESLight Weight And Modular Design

- Compact structure and small limit of size.

- Variable frequency speed regulation and stable operation.

- Complete, safe and reliable protection device.

- Integrated transmission, energy-saving and high efficiency.

- Silent drive, low noise and environmental protection.

Product AdvantagesLow-energy and Maintenance-free

Low-energy and Maintenance-free

- The total power of crane reduce about 30%, energy conservation and environmental protection.

- The multi -in-one integrated transmission mechanism has less intermediate ring knot and high transmission efficiency.

- Adopt frequency control, high and low speed ratio 1:10, work efficiency increased by more than 20%.

- The "Maintenance-free and easy maintenance" design concept reduces customer maintenance costs.

- It uses advanced processing technology and high -quality imported components. Its failure rate has been greatly reduced compared to traditional GB crane, helping customers reduce operating costs.

Intelligentialize

- World's leading electrical anti- sway technology can be installed on the crane to achieve precise positioning.

- Advanced electrical control technology can achieve the semi-automatic and automatic control lifting, so that the crane becomes " Lifting robot ."

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.