DESCRIPTIONEnsure safety in hazardous environments

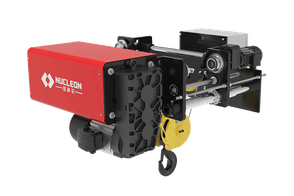

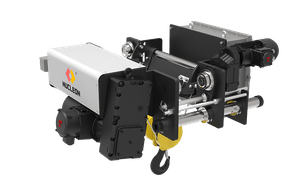

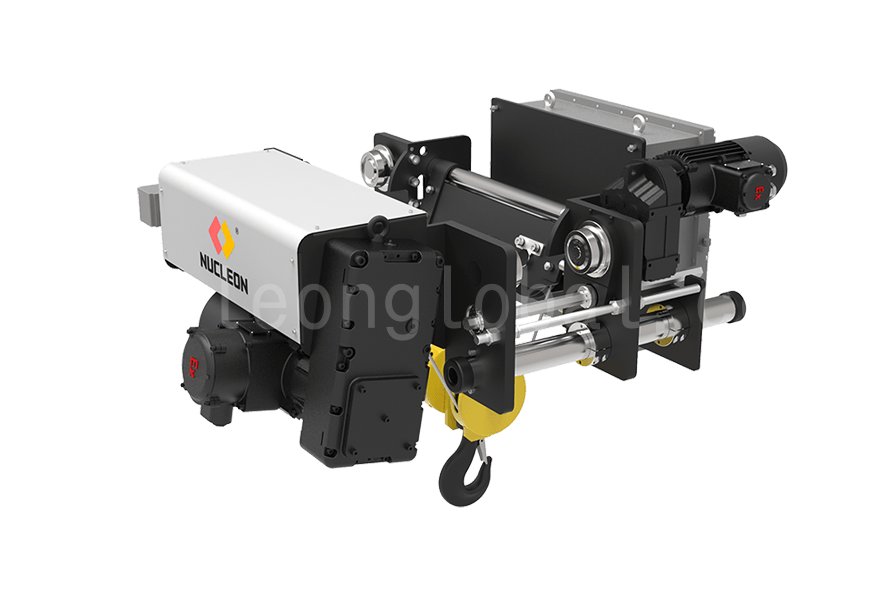

The motor is a flameproof three-phase asynchronous motor with variable frequency electromagnetic brake. The motor speed is stable without impact, has a large overload capacity and high mechanical strength, and is especially suitable for short-term or intermittent operation, frequent starting and braking equipment. Motor standard insulation class F, protection class IP65.

The motor is equipped with a spring-loaded electromagnetic safety brake, which is released when the power is supplied and braked when the power is off. The brake can brake safely up to 1 million times.

The reducer is a fully enclosed hard tooth surface reducer. The gears are carburized and quenched, the hardness of the tooth surface can reach 58-62HRC, the bearing capacity is high, and the working noise is low. Reducer case cover with high strength and good performance.

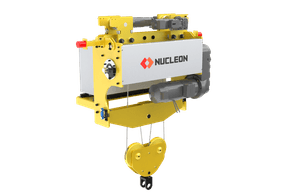

It is suitable for working in explosive gas environments such as the explosion-proof level is not higher than level B or C or the environment is formed by combustible gas, steam and air and ignition temperature group is not lower than T4 (135 ℃). The applicable hazardous area is zone 1 or zone 2, and is not applicable to zone 0.

PRODUCT FEATURESMinimize the risk of explosion and electrical failure

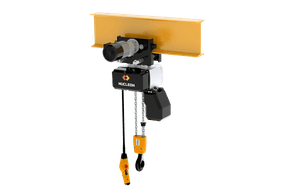

- Enclosure: The hoist is enclosed in a specialized housing that is designed to contain any potential explosion within the enclosure. This prevents sparks or flames from escaping and coming into contact with the hazardous atmosphere.

- Spark-Resistant Materials: The components of the hoist, such as the motor, wiring, switches, and control mechanisms, are made from spark-resistant materials. This reduces the risk of generating sparks that could ignite flammable substances.

- Sealed Design: Explosion proof electric hoists have a sealed design that prevents the entry of flammable gases, vapors, or dust into the internal components. This further minimizes the risk of ignition.

- Corrosion Resistance: The hoist is built to withstand corrosive environments. Special coatings or materials are used to protect the hoist from chemicals or other substances that could compromise its integrity.

These construction features collectively aim to minimize the risk of sparks, flames, or electrical malfunctions that could potentially trigger an explosion in volatile environments.

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.