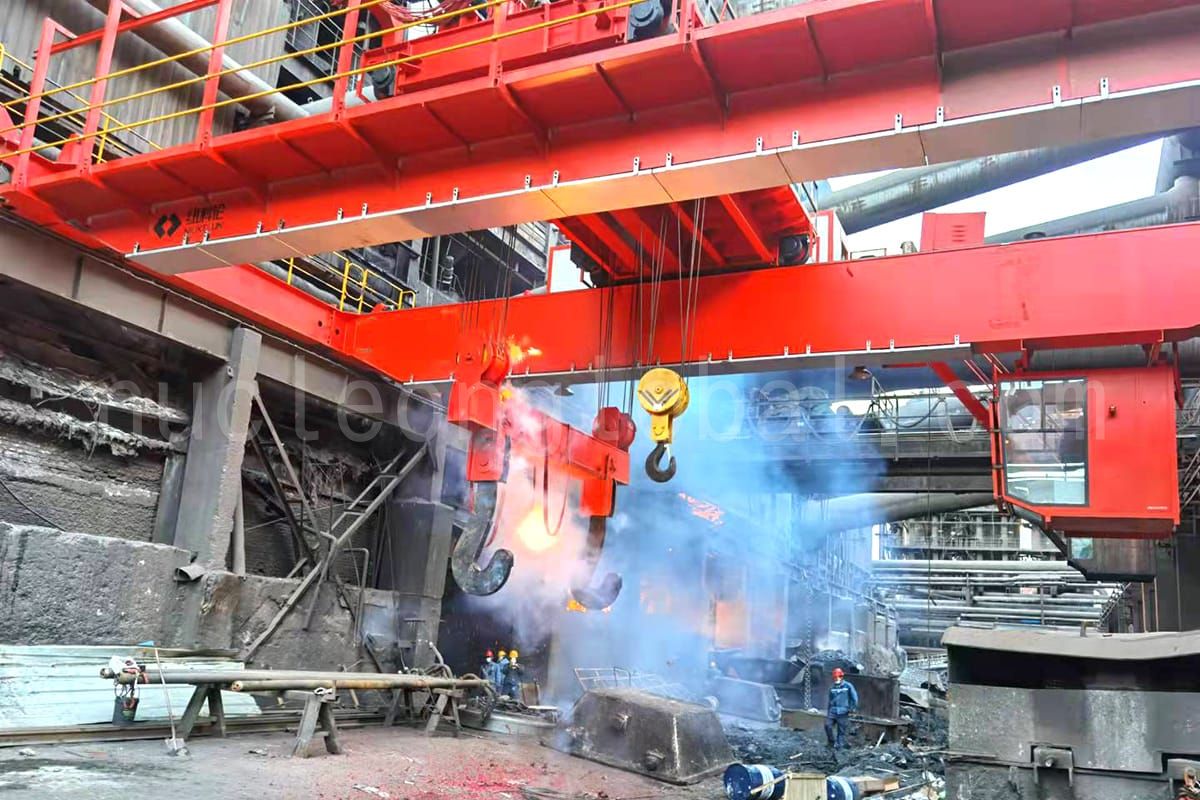

DESCRIPTIONSpecialized cranes for lifting molten metal in harsh environments in the metallurgical industry

Ladle overhead crane is the Nucleon-developed special crane in response to the lifting of molten metal in the harsh environment of the metallurgical industry.

Metallurgical cranes play a crucial role in the efficient handling, transportation, and processing of metals in industries such as steel mills, foundries, metal forging, and metal fabrication. They contribute to improving productivity, reducing manual labor, and ensuring the safety of workers involved in metallurgical operations.

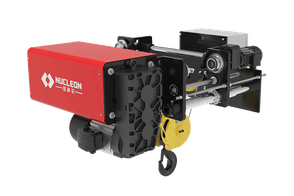

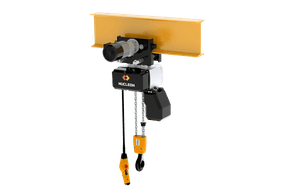

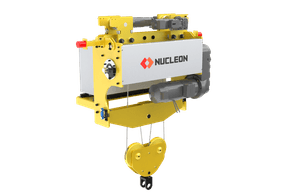

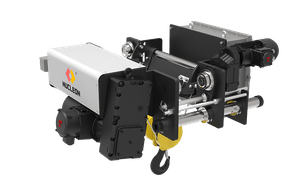

Overhead crane for metallurgy is designed with many technologies such as multiple protection, redundant mechanism and advanced control. Electric hoist for metallurgy can be used for small tonnage (less than 16t) and special trolley for metallurgy can be used for large tonnage (16t and above). The traveling mechanism adopts special motor reducer for metallurgy, and various speed control systems can be used for control as required.

The crane for metallurgy includes electric hoist for metallurgy, single beam crane for metallurgy, overhead crane for metallurgy and so on.

PRODUCT FEATURESSafe and reliable, durable, protective measures and more features

- High lifting capacity: Metallurgical cranes are designed to handle extremely heavy loads, often ranging from several tons to hundreds of tons. They are built with robust structures and powerful lifting mechanisms to ensure safe and efficient handling of heavy metal materials.

- Heat resistance: Metallurgical processes often involve high temperatures, so these cranes are designed to withstand heat and provide safe operation in demanding environments. They may include heat-resistant materials, cooling systems, and protective measures to prevent damage from extreme heat.

- Specialized lifting attachments: Metallurgical cranes are equipped with various lifting attachments such as tongs, magnets, and grabs specifically designed for handling molten metal, ingots, slabs, or other specialized metal products.

- Precise and controlled movements: To ensure precise placement of heavy loads, metallurgical cranes are equipped with advanced control systems that allow operators to maneuver the crane with accuracy and efficiency.

- Multiple protection measures: NUCLEON cranes are equipped with multiple safety devices, such as overload protection systems, emergency stop mechanisms, and anti-collision systems to enhance safety during operations.

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.