DESCRIPTIONThe crane is high temperature resistant and can adapt to harsh environments in metallurgical operations

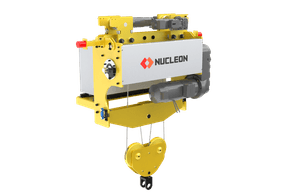

Metallurgical overhead crane is a special type of lifting product developed by NUCLEON for the needs of lifting molten metal in harsh environments in the metallurgical industry. It is suitable for smelting, casting, quenching and other occasions in the metallurgical industry.

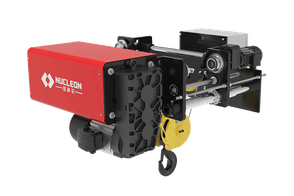

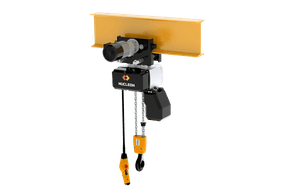

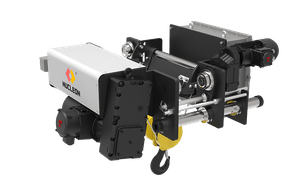

Metallurgical overhead cranes adopt lightweight, modular and parameterized design. It adopts technologies such as multiple protection, redundancy of institutions and advanced control. Metallurgical electric hoists can be used for small tonnages, metallurgical special trolleys can be used for large tonnages, metallurgical special motor reducers can be used for operating mechanisms, and various speed control systems can be used.

Heavy and super heavy operating modes (A5-A8)

Product featuresHigh safety and thermal protection

- Protection from exposure of extremely aggressive environments;

- The increased level of reliability and safety;

- The increased thermal protection of cabin and equipment;

- Smooth travelling over the entire range of loads;

- Ingress protection rating of electrical room and equipment not less than IP54;

- Appliance of heat resistant protecting sleeves for cable laying;

- The increased maintainability, quick unit replacements;

- Possibility of long-term work after one motor failure before its replacement;

- No limits of working motions combination;

- The increased safety margins of components and ropes;

- Automated collection and display of information about equipment condition and actual parameters of the crane.

Product advantagesSafe, durable and efficient

- Excellent production efficiency

Suitable for frequent working environments, can meet 24h operation. - Adapt to harsh environments

It is used to load cast iron water into the loading channel of the converter or electric furnace, and to transport the ladle containing molten steel to the receiving device or to transport the molten steel to the ladle furnace to further purify the metal. - High security performance and automation requirements.

Equipped with a variety of transmission control schemes,there is sufficient margin for the selection of electrical components and wires, and sometimes it is used to reduce capacity.

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.