DESCRIPTIONThe applicable clean room level is high, up to 100 levels(ISO5)

Clean room classification system

The FS209E clean room classification system has six clean room cleanliness classes: Class 1, Class 10, Class 100, Class 1,000, Class 10,000, and Class 100,000. ISO 14644-1 replaced FS209E in 1999 for Europe and in 2001 for the United States.

The clean room given names under Federal Standard 209e are:

- Class 100,000 clean room (dirtiest)

- Class 10,000 clean room

- Class 1,000 clean room

- Class 100 clean room

- Class 10 clean room

- Class 1 clean room (cleanest)

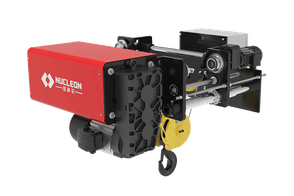

The latest portable gantry crane developed by NUCLEON CRANE can already reach the 100th level of the above standards.

It is often used in the environment of semiconductor, food and pharmaceutical production, and physical and chemical research laboratories.

Maintain the sterile conditions of the clean room.

Heavy and super heavy operating modes (A3-A5)

PRODUCT FEATURESEnergy saving and environmental protection, intelligence, high cleanliness

In the production design of portable Gantry Crane clean room cranes, the standards of class 100 laboratories are considered. According to the cleanliness design of the clean room, the clean room crane can be dust-free and stain-free during the material handling process, and the fine particles are controlled within a small range. Maintain environmental hygiene while handling materials.

- Crane cleanliness level can reach 100 levels

- Less adsorption of dust, not easy to generate static electricity;

- Complete protection device, safe and reliable;

- Simple control, easy operation and easy maintenance

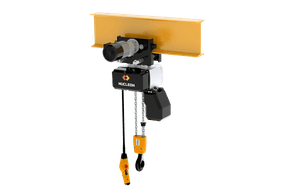

Product advantagesSmall shape, Prevent dust,High environmental protection,Accurate positioning,Safe and reliable

- The class 100 clean room gantry crane itself has a small size and a small limit size to meet the hoisting needs of a 100-level clean room or laboratory.

- It can reach a higher lifting height in a limited space and has a wide range of hoisting coverage.

- The main structural parts such as the main beam, outriggers, ground beams, and connecting beams are made of stainless steel 304.

- The components such as the wheel axle and bearing chamber are coated to avoid corrosion of the structural body or dust particles.

- The vehicle is treated with anti-static electricity to avoid dust absorption.-Reduce the labor intensity of operators.

- Gears and other components use special grease for low-dust clean rooms to effectively inhibit the volatilization and diffusion of oil molecules and avoid environmental pollution.

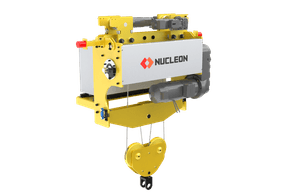

Applications:Portable Gantry Crane for Class 100 Clean Rooms is used in a class 100 clean room(GMP workshop) to meet the cleanliness, temperature and humidity required by the clean room.

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

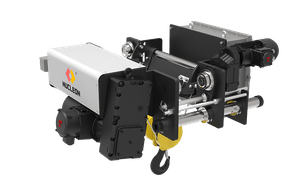

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.