In enhancing industrial efficiency, overhead cranes play an indispensable role in heavy lifting and material handling. However, a key issue often encountered during operation is rail biting – excessive wear and tear of the crane wheels against the crane rail track. This not only leads to increased maintenance costs for the bridge crane but also poses significant operational and safety risks. Understanding the complexity of rail biting, including its occurrence and potential hazards, is crucial for maintaining the integrity and performance of these vital machines.

Overhead Crane Wheel Rail Biting Hazards

Reduced Lifespan of Crane Wheels

Typically made from cast steel and undergoing processes like quenching, overhead crane wheels generally have a lifespan of over 10 years. However, rail biting significantly reduces this lifespan, adversely affecting production safety and efficiency.

Wear and Tear of Crane Rails

Rail biting, involving rigid contact between crane wheels and crane rails, intensifies the wear on the rails. As the wear increases, the stability of the crane trolley and the entire crane system is compromised, impacting safety. Replacing worn-out crane rails requires substantial manpower, resources, and financial investment, causing major disruptions to safe production.

Damage to Electrical Equipment

The uneven movement caused by rail biting can impact electrical contact points, leading to poor connections. Frequent abnormal movements may stretch or compress electrical cables, accelerating wear and potentially causing cable breakage. Prolonged rail gnawing can also intensify vibrations in the overhead crane, affecting the stability of electrical components and leading to potential damage over time.

Impact on Facility Structure

The noise and vibrations from rail biting, along with the horizontal lateral forces generated during crane operation, can cause lateral deviations in crane rails and vibrations in equipment. This can lead to loosened bolts fixed on the crane rail track. Abnormal vibrations from the crane can also affect the structural integrity of the facility, causing damage.

Risk of Derailment

Severe wear and tear on wheels or rails can lead to situations where the crane wheels climb onto the top of the rails, potentially causing derailment and serious safety incidents.

Reduced Operational Efficiency and Additional Financial Loss

Rail biting results in uneven crane operation, affecting work efficiency and increasing downtime due to maintenance. Frequent rail biting escalates maintenance costs, necessitating more frequent replacements of damaged parts like crane wheels and rails. Operational disruptions due to crane malfunctions can lead to project delays, incurring additional economic losses.

What is Overhead Crane Wheel Rail Biting

Rail biting in overhead cranes refers to a phenomenon where, during the operation of the crane's main or auxiliary trolley on the rails, the wheel flanges of the crane trolley are supposed to maintain a certain gap from the sides of the rails. However, for various reasons, if the wheel flanges come into contact with the sides of the rails, it generates horizontal lateral thrust. This results in abnormal wear or damage to the crane wheels against the rails, a condition commonly known as rail biting in EOT cranes.

How to Identify Overhead Crane Wheel Rail Biting

Wear on Crane Wheel Flanges

Observing abnormal wear on the flanges of crane wheels is a key indicator of rail biting. If there are noticeable burrs on the inner side of the crane wheels' flanges, correlating directly with wear, it's a clear sign of rail gnawing. Under normal operation, such wear or burrs should not occur. The presence of burrs on the wheel flanges significantly impacts the appearance and indicates wear, making it an important method of detection.

Friction Marks on Crane Rails

Obvious, polished friction planes on the sides of the crane rails, sharp edges on the guide rails, and white, shiny spots on the top surface of the rails indicate rail biting. Since detecting gnawing rail in its early stages can be challenging, examining the appearance of the crane rail track side can help determine its occurrence. If there are uneven or abnormal running marks on the rail sides, differing from the regular trajectory of the crane wheels, it's indicative of rail biting. Inspecting these marks can reveal the timing and severity of the issue, aiding in its resolution.

Deviation in Braking and Starting

Apart from visual inspection of the wheels and rails, observing the overhead crane's behavior during braking and starting can also identify rail biting issues. If the bridge crane exhibits unusual behavior during braking and starting, such as excessive resistance, slow start-up speed, or extended braking distance, and these issues are frequently observed, it may indicate the presence of rail biting. This deviation can be a crucial sign that the crane is experiencing issues with its wheels or tracks.

Changes in Crane Wheel and Rail Gap

In normal operation, a specific standard gap should be maintained between the crane wheel flanges and the crane rails. A noticeable increase or decrease in this gap can suggest misalignment or unevenness in the crane rail track or the crane end truck. Such irregular gap changes can affect the stability and efficiency of the crane, potentially leading to more severe rail biting issues.

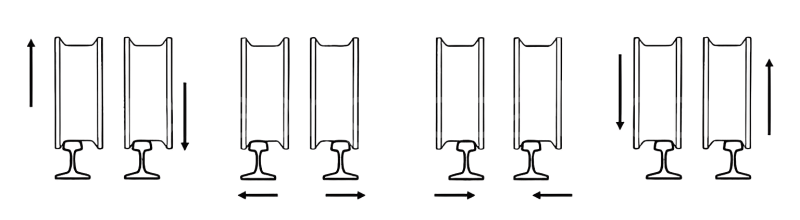

Crane Skewing

If an overhead crane shows signs of skewing during operation, it is often due to issues such as misaligned wheels, uneven crane rails, or structural problems within the crane itself. Skewing not only affects the operational efficiency of the crane but also exacerbates wear on the wheels and rails, increasing the risk of rail biting. Regular inspections and maintenance of the crane are key to preventing skewing and ensuring correct alignment and stability.

Noise Issues

The piercing noise produced during rail biting is caused by abnormal friction between the crane wheels and the crane rails. This noise is not only discomforting but also serves as a clear warning sign of gnawing rail. In severe cases, rail biting can even cause the EOT crane to exhibit a jumping motion, known as "climbing the rail." This can damage the crane structure and severely impact the safety and precision of operations. Therefore, any unusual noise should prompt immediate inspection and corrective measures.

Analysis of Causes Leading to Rail Biting in Overhead Crane Wheels

Several factors contribute to rail biting in overhead cranes, such as crane rail issues, crane wheel problems, bridge frame deformation, synchronization issues in the transmission system, and mismatches between crane wheels and crane rails.

Railway Issues

- Rail Deformation: Frequent operation of the crane can lead to intermittent pressure and internal alternating stress on the rails, causing deformation or displacement. While overhead cranes are designed to travel in a straight line, real-life operations involving load-bearing and angled lifting can introduce additional stress, increasing the risk of rail biting. Factors like geological subsidence can also affect the foundation of the crane rails, leading to deformation. Variations in management styles and operator skills across different enterprises can also impact the rails adversely.

- Improper Railway Installation: Excessive horizontal bending or straightness errors exceeding 2mm can lead to fixed segment biting rail.

- Railway Gauge Issues: A too wide gauge can cause the outer side of the wheel flange to bite the rail, while a too narrow gauge can cause the inner side to do so.

- Vertical Height Difference in Rails: A significant vertical height difference between two rails in the same cross-section can cause rail biting on both the higher and lower rails, which might be due to installation, maintenance, or foundation sinking of the facility's pillars.

- Railway Parallelism Difference: If the two rails are not parallel, forming an "outward eight" or trumpet shape, it can lead to rail biting.

Crane Wheel Problems

- Manufacturing Errors in Wheels: If the diameters of the two driving wheels differ, the crane will travel at different speeds on each side under the same motor speed, creating a "circle drawing" effect and leading to rigid contact between the wheel flange and the rail on both sides, causing rail biting.

- Excessive Horizontal Deviation in Wheels: The horizontal deviation during wheel installation should not exceed 1/1000 of the wheel's measured length, and the skew directions of a pair of wheels on the same axis should be opposite to avoid rail biting.

- Excessive Vertical Deviation in Wheels: If the wheel end face line forms an angle with the plumb line, causing the wheel to be in a tilted state, the vertical deviation should not exceed 1/400. This type of rail biting is typically associated with the driving wheel and not the driven wheel.

- Unequal Wheel Distance Along the Diagonal: Discrepancies in straightness or unequal distance along the diagonal of two wheels on the same track can also lead to biting rail .

Bridge Frame Deformation

Prolonged operation beyond the load capacity, residual stress in the main beam of the crane, and other factors can cause deformation in the main beam, end beams, and frame of the crane, leading to skewed wheels and rail biting.

Transmission System Asynchrony

If two motors of the large car have different speeds or one motor is damaged, it can cause different linear speeds of the wheels, leading to the entire crane body skewing and rail biting. Additionally, Large discrepancies in the transmission gap between couplings or a failure to start the wheels simultaneously can also result in rail biting. Imbalances in gear clearances, loosened shaft keys, or other issues within the crane's driving mechanism can further exacerbate this problem.

Mismatch Between Crane Wheels and Rails

Incompatibility between the crane wheels and the crane rails can lead to rail biting. If the gap is too small, the wheel flange will make contact with the side of the rail, leading to rail biting; a too-large gap can have a similar effect. If all four wheels are not on the same horizontal plane, one of the driving wheels may become suspended or slip, causing the crane to skew during operation. Additionally, debris on the crane rail track can cause uneven wheel speeds, contributing to rail biting.

Solutions for Overhead Crane Wheel Rail Biting Issues

Rail Alignment

Once new rails are installed, they must undergo thorough adjustments before being put into use. Before beginning the adjustment process, ensure that all necessary tools are prepared, such as steel tape measures, level instruments, tensioners, and fine steel wires.

- Measuring Rail Gauge Deviations: Use a steel tape measure to determine the gauge (distance) between the two rails. Accurately measuring the gauge deviation is crucial to ascertain whether the parallelism of the rails meets the operational requirements of the overhead crane. If the rail gauge deviation is too large, it inevitably leads to rail gnawing in the crane. Thus, precise and effective measurement of rail gauge discrepancies, with data accuracy down to the millimeter, is essential in rail biting inspections.

- Checking Rail Straightness and Elevation: Adjust the rail's horizontal straightness using tensioners and fine steel wires, and use level instruments to check if the heights of the two rails are uniform. Inspecting and adjusting the straightness and elevation of the rails is vital to assess the quality of rail installation and their operational condition. If there are significant errors in rail straightness or elevation, it can be concluded that the overhead crane is likely to experience rail gnawing during operation. Therefore, detecting issues with rail straightness and elevation is an important means of diagnosing rail biting in bridge cranes. By examining and adjusting these aspects, rail biting issues can be prevented.

- Adjusting Old Rails: The method and requirements for adjusting old rails are similar to those for new rails, but it's crucial to conduct a detailed inspection beforehand. This includes checking for any cracks or breaks in the rails, ensuring all bolts and nuts are secure, and inspecting all rail pads and shims for damage. When correcting the entire rail, use appropriate tools and methods to measure the gauge, levelness, and straightness of the two rails, and record any discrepancies.

Improper installation of rails or non-compliance with technical installation requirements, leading to deviations in rail span tolerance and elevation differences between rails of the same span, can cause rail biting in the crane. The installation standards for rails dictate that the relative elevation of two rails should not exceed 10mm, straightness error should be within 3mm, lateral displacement at the joints should not be more than 1mm, and the permissible gauge error should not exceed 15mm. To address rail issues, adjustments should primarily focus on correcting height differences while also adjusting the gauge. Common steel plates, chosen based on measured errors and ensuring a smooth, even surface, can be used as shims. The rails should be solidly filled underneath to prevent suspension and secured with bolted rail clamps. This method is simple, economical, and ensures that the adjusted rails meet the required standards for height differences.

Inspecting Overhead Crane Wheels

Initially, inspect the crane wheels for any cracks, tread peeling, or indentations. Early wear can cause the wheel tread to collapse or flatten. The wheel flange thickness wear should be ≤5%, and tread wear ≤1.5%, with no surface pitting, to meet usage standards. If the diameter difference between two driving wheels exceeds 0.2mm of their diameter, or for driven wheels, exceeds 0.5mm, the wheels should be re-machined to achieve uniform basic dimensions. The diameter difference between driving and driven wheels should not exceed 3mm.

- Measuring the Diagonal Data of Large Car Wheels: Select a section of track with good linearity, drive the crane onto this track, and use calipers to find the center of the wheel grooves, drawing a straight line accordingly. Hang a plumb line and mark the midpoints on the track directly beneath the plumb. Do this for all four wheels to find the measurement points for the wheel diagonals. Then, move the crane away and measure the distance between the diagonal wheel midpoints with a steel tape measure. This distance is the wheel diagonal. Adjustments should be made for wheel span, diagonal, and positional differences: the deviation in wheel span and diagonal for the large car should not exceed +7mm, and for the small car should not exceed +3mm, with positional difference not exceeding 2mm. If these values do not meet the standards, adjust the wheel bearing spacers on either side to reposition the wheels. Alternatively, enlarge the bolt holes in the end truck bearing boxes to adjust the positioning.

- Wheel Diameter Measurement: Measuring the wheel diameter is a crucial inspection method. It's important to check for size discrepancies and wear in the wheel diameter. Determining wheel wear can reveal abnormal wear on the wheels. If wear is pronounced at common points, it indicates that the overhead crane has experienced rail biting during operation. Analyzing the position of the worn wheels and the corresponding track section can help identify the location of the rail biting issue, providing strong support for subsequent management.

Replace worn wheels in pairs to eliminate the effects of diameter differences on operation and adjust the installation precision of the wheel assembly to reduce manufacturing errors. When installing wheels, horizontal deviation should be controlled within △≤ L/1000 (L being the measured diameter of the wheel along the parallel reference line) and vertical deviation within △≤ H/1000 (H being the measured height of the wheel in the vertical direction).

Inspecting and Adjusting the Drive Mechanism:

- A thorough inspection of the drive mechanism is necessary. If there is a significant gap in the couplings or gearbox, repairs or replacements are required.

- After installing the driving wheel of the large car, the alignment of the horizontal axis between the integral coupling, gearbox, and driving motor should be checked and adjusted. To prevent shifts, positioning blocks should be welded securely to the gearbox.

- The speed of motors in the drive mechanism should be tested and adjusted. If the speeds of the motors on both sides remain inconsistent, it is advisable to replace them with motors of the same make and model for uniformity.

- Ensuring that the brakes on both ends of the crane are coordinated and fully open during operation, without any additional frictional resistance, can prevent the occurrence of unequal braking torque and subsequent rail biting during braking.

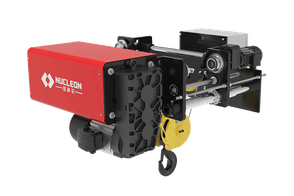

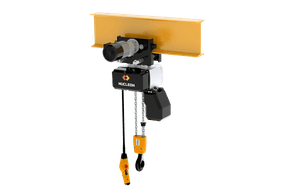

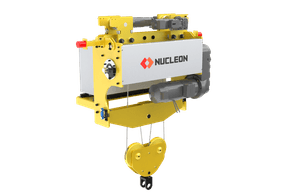

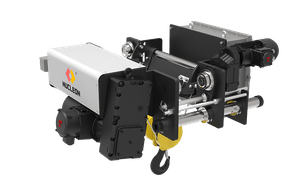

Nucleon's Advantage to Preventing and Resolving Overhead Cranes Rail Biting

As an expert in the field of crane, I understand that selecting a reliable crane manufacturer before purchase is crucial to minimize the occurrence of issues like rail biting. At Nucleon, we pride ourselves on our preventive and solution-oriented approach towards the rail biting problem in our overhead cranes and gantry cranes, particularly our European standard crane.

Innovative European Standard Crane Design:

Our cranes feature a lightweight design with full-vehicle variable frequency speed control. This allows for stepless speed control of all crane mechanisms (with a wide speed range and a ratio of 1:10). Such a system ensures that starting, braking, and acceleration/deceleration are smooth and gentle, significantly reducing the adverse impact of shock loads on the crane's main load-bearing components. This design effectively reduces the lateral thrust exerted on the crane trolley wheels due to inertial loads at the start and stop moments of the crane trolley, thereby considerably lowering the incidence of rail biting.

Strategic Design Features:

In designing our cranes, we install horizontal guide wheel groups on one side of the crane trolley end beam. This ensures that there is always a safe gap between the crane trolley wheels and the tracks, effectively preventing rail biting. These features can be customized based on budget and are not mandatory. However, for cranes with a span exceeding 40 meters, a correction device (mechanical or electrical) for the trolley mechanism is essential.

Experienced Installation Team:

With over a decade of experience in crane installation and servicing more than 1000 overhead crane and gantry crane projects, our engineers meticulously adjust installations according to on-site conditions, significantly reducing the likelihood of rail biting issues.

Dedicated After-Sales Support:

Should a rail biting incident occur, Nucleon has a professional after-sales team ready to assist. We offer remote guidance or on-site resolution by our after-sales engineers, ensuring quick and efficient problem-solving for our clients.

At Nucleon Crane, we are committed to delivering not only high-quality cranes but also comprehensive solutions for common challenges like rail biting, ensuring our clients' operations run smoothly and safely.

Conclusion

The maintenance of overhead cranes, especially the prevention and resolution of rail biting, involves addressing a range of factors, including crane rail deformation, crane wheel manufacturing, installation errors, bridge frame deformation, and synchronization issues in the transmission system. Emphasizing preventive measures and regular maintenance is vital. Early detection and prompt repair can significantly reduce the occurrence of rail biting, ensuring safe and efficient production. A comprehensive understanding and systematic management of these factors can effectively minimize the incidence of rail biting, thereby ensuring the safety and efficiency of crane operations.

FAQ

1. How Often Should I Inspect My Overhead Crane for Rail Biting Issues?

Regular inspections are crucial. It's recommended to inspect your crane at least bi-annually or as per the manufacturer's guidelines.

2. Who Should Perform Maintenance Checks for Rail Biting Issues?

Qualified maintenance personnel or crane service technicians should conduct these checks to ensure accuracy and safety.

3. Is Specialized Training Required for Maintenance Teams Handling Wheel Rail Biting?

Yes, maintenance teams should be trained in crane operation, diagnosis of common issues like rail biting, and safety protocols.