DESCRIPTIONWide application, high versatility and good maintainability

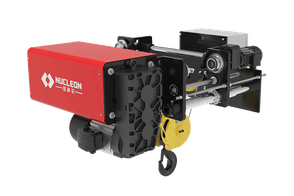

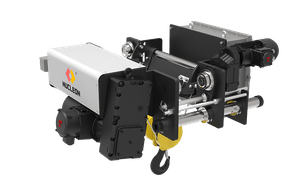

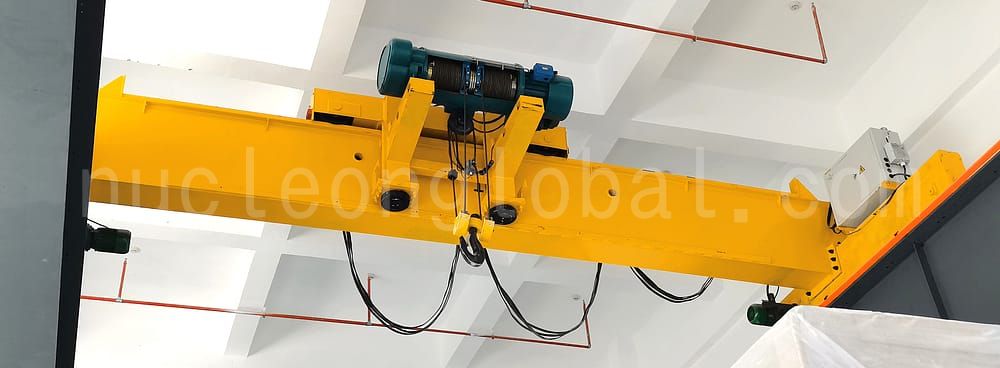

single girder EOT crane is characterized by more reasonable structure and higher strength steel as a whole, Used together with CD model、 MD model electric hoist as a complete set , it is light duty crane with a capacity of 1 to 20 tons. The span is 7.5-28.5m. Working grade is A3-A4. Working temperature is-25℃ to 40℃.

This product is widely used in plants, warehouses, material stocks to lift goods. It is prohibited to use the equipment in the combustible, explosive or corrosive environment.

This product has two operational methods, ground control or operational room which has open model and closed model and can be installed on left or right side according to the practical situation . And the direction of entering the gate has two forms, from the side and the end in order to satisfy the users, choice under different conditions

PRODUCT TYPESLDY Model Electric Single Girder Crane

LDY single girder Metallurgical crane mainly used for lifting molten metal.

Lifting capacity ≤10t, Dealing with special thermal bafflfflffle felt for main girder , Work environment temperature-20-60℃.

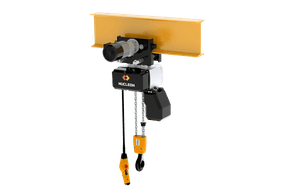

LDP Model Electric Single Girder Crane

LDP model electric single beam crane belongs to very low clearance light duty lifting equipment.

Electric hoist is at one side of main girder, so can increase service space of hook and reduce the cost.

It is widely used in the situation that clearance height of work shop is low.

LX Model Single Beam Suspension Crane

LX model single Beam Suspension motor crane and CD、MD model electric hoist are used together as a complete set . It is a light duty track traveling crane with trajectory which applies to and used at machinery assembling sites and warehouses.

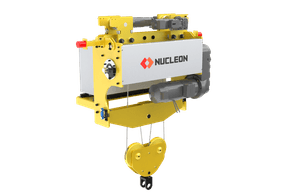

LDC low headroom single girder overhead crane

Low-headroom design, compared to normal type single girder overhead crane, the LDC type single girder overhead crane can have higher lifting height, and it is more space-saving.

LB Type Explosion Proof Electric Single Girder Crane

Safe and reliable, beautiful appearance, strong explosion-proof, etc.

For each of the Explosion-proof sign is ExdⅡBT4、ExdⅡCT4、DIPA21TA、T4.

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.