DESCRIPTIONSpecial crane for anode charcoal block roasting for aluminum electrolysis in carbon industry

Suction overhead crane for baking is a special crane serving the roasting of anode carbon blocks for aluminum electrolysis in the carbon industry. Effectively improve the production efficiency of the anode roasting workshop, greatly improve the working environment of the workshop, and reduce the labor intensity of workers.

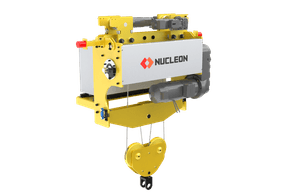

Material suction and discharge crane for baking mainly includes crane bridge, crab, dust handling system for material suction and discharge, anode transfer mechanism (optional), traveling mechanism of trolley and electric control system. Variable frequency speed regulation is adopted for crane operation, lifting and lowering of the material pipe and fixture and the whole vehicle PLC system is intelligently controlled.

Product AdvantagesIntegrate multiple functions into one to improve production efficiency.

- Loading: Load the unburned anode block (green block) into the baking furnace pit.

- Filling: Fill the granular coke in the material box into the space between the baking furnace and the anode block and cover the top.

- Suction: Suck the filled material in the furnace into the bin.

- Discharge: Take out the baked anode block (baked block) from the baking furnace and send it to the conveyor belt or the designated place.

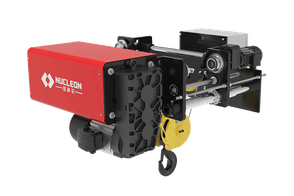

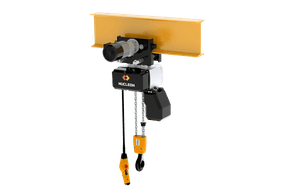

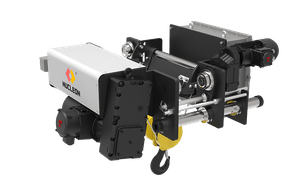

- Other auxiliary lifting operations: The crabs are equipped with auxiliary suction pipes to clean the flue and remove dust. The bridge is equipped with 10t electric hoist to carry the burner and maintain the baking furnace.

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.