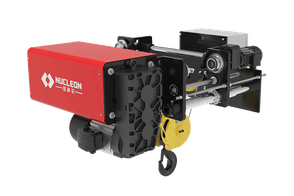

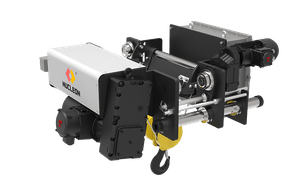

DESCRIPTIONStable structure, compact and high integration.

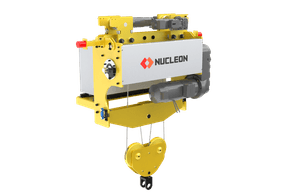

Truss gantry crane adopts lightweight, modular design. Lifting mechanism of the gantry beam hoister adopts windlass crab with slow lifting speed, compact structure and high integration.

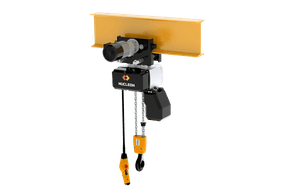

Traveling mechanism of the trolley is drove by three-in-one drive device and the control mechanism adopts the advanced variable frequency and speed regulation control system; The lifting mechanism of the hoist gantry crane for accessory hoisting adopts CD1 / MD1 electric hoist with simple structure, stable performance and durable performance. Traveling mechanism of the trolley is driven by vertical driving device, and the control mechanism adopts single or multiple linkage controls.

Engineering gantry crane adopts double-beam and double- rail structure, and the main beam is a triangular truss structure, which is fabricated in sections; The rigid leg is an inverted triangle structure welded by steel pipes, the flexible leg is a single steel pipe, and all the auxiliary supporting rods are connected by pins. The single main beam truss structure is adopted for the hoist gantry crane for accessory hoisting. The main beam is a regular triangle structure and the legs are inverted trapezoidal structure welded by profile steel.

PRODUCT FEATURESSimple structure, stable performance and durable performance

- Stable structure and excellent performance.

- Simple operation and convenient use.

- Safe and reliable, easy to disassemble.

Zero Speed Hover

Ensure that the crane moves slowly and accurately as it approaches its destination.

Electric Anti-sway Function

Can automatically limit the sway of the loader in the process of handling, faster handling and more accurate positioning.

Multi-hook Coordination

Monitor and control position difference of multiple hooks to make the hooks run synchronously at the same speed.

Dead Slow

Dead slow function can ensure the stability of the control system and slow, accurate movement when the crane is moving and loading.

Multi-trolley Synchronization

Position difference of multiple cranes can be monitored and controlled to make the crane operating mechanism run synchronously at the same speed.

Speed Expansion Function

Our cranes can add sub-low speed and sub-high speed function regulation except for low speed and high speed, which is practical and efficient.